Blade design is a critical factor in broadhead performance. While weight, arrow configuration, and shot placement are vital, a blade’s shape and construction directly dictate penetration, cutting efficiency, and reliability. By understanding these design principles, hunters can make informed choices that lead to more consistent and ethical outcomes. This article explores how blade design influences performance, specifically highlighting the practical advantages of fixed blade broadheads.

Why Blade Design Matters More Than Many Expect

When a broadhead hits an animal, the blade immediately gets to work. Its efficiency depends on often-overlooked design details.

Effective blade design helps:

- Reduce resistance on impact

- Maintain straight-line penetration

- Create clean, effective wound channels

A poorly designed blade can waste energy, deflect on impact, or limit penetration even when shot placement is solid.

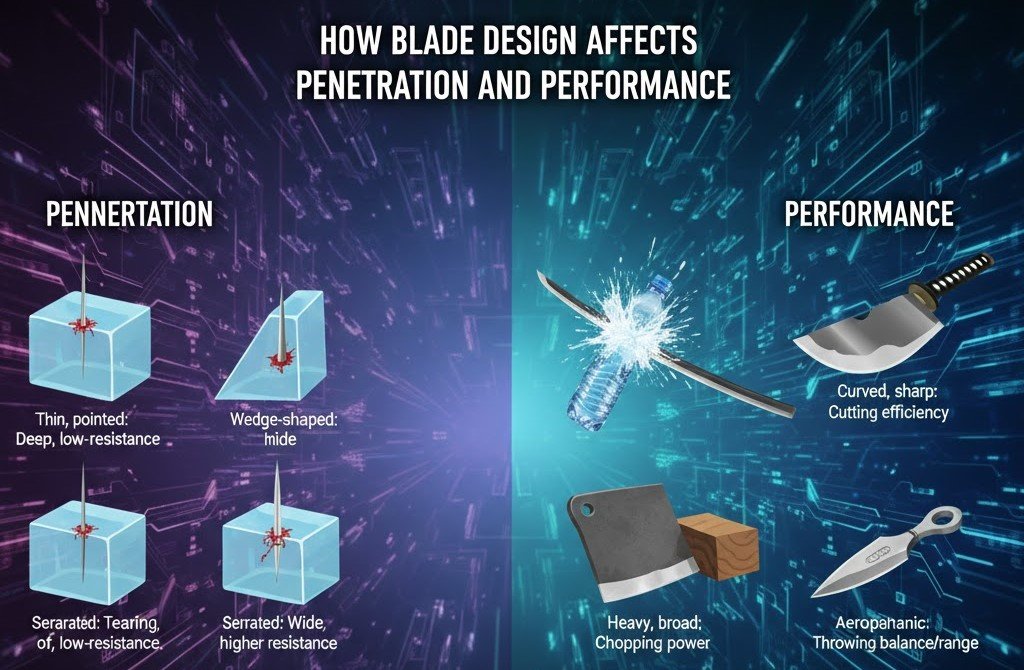

Blade Angle and Penetration Efficiency

The blade’s edge angle is a critical aspect of its design. Steeper angles cut aggressively but face more resistance, while shallower angles penetrate more easily by slicing rather than punching.

Blade angles influence:

- How smoothly the broadhead enters the target

- How much force is required to continue penetration

- The ability to pass through hide, muscle, and bone

Designs that balance cutting power with efficient slicing tend to perform more consistently across different shot scenarios.

Number of Blades and Their Impact

Broadhead blade count directly impacts performance. While more blades create larger wound channels, fewer blades typically penetrate deeper by reducing surface resistance.

Key considerations include:

- Fewer blades often mean better penetration

- Additional blades can increase cutting surface

- Balance between damage and depth is essential

Blade count should align with hunting conditions, draw weight, and expected shot distance.

Fixed Blade Broadheads and Structural Reliability

Fixed blade broadheads are durable and reliable, with exposed blades and no moving parts to fail on impact.

This design offers:

- Immediate cutting action upon contact

- Consistent performance regardless of speed

- Strong structural integrity during penetration

Reliability is especially important in unpredictable field conditions where equipment failure is not an option.

Blade Thickness and Material Strength

Blade thickness impacts durability and penetration. Thicker blades are stronger and less prone to bending or breaking but face slightly more resistance. Thinner blades penetrate easily but must withstand impact forces.

An effective balance:

- Maintains sharpness through impact

- Resists deformation on bone contact

- Preserves cutting efficiency throughout penetration

Material quality and heat treatment also play a role in long-term performance and edge retention.

Cutting Diameter and Wound Channel Effectiveness

Cutting diameter is the width of the wound channel made by the broadhead. Larger diameters cause more tissue damage but may reduce penetration if resistance is too high.

Blade design influences:

- Width of the cut

- Shape of the wound channel

- Blood loss and recovery effectiveness

Efficient designs focus on clean, controlled cuts rather than excessive drag.

Flight Stability and Blade Profile

Blade design impacts both terminal performance and flight. Large, aggressive profiles can catch the wind and alter arrow flight unless the setup is precisely tuned.

Streamlined blade profiles:

- Improve long-distance accuracy

- Reduce wind drift

- Support consistent grouping

Proper tuning ensures that blade design enhances performance rather than creating instability.

Penetration Through Bone and Dense Tissue

Big game animals often present shots that involve heavy muscle or bone. Blade design must support penetration without deflection or failure.

Strong blade designs:

- Maintain alignment on impact

- Reduce the chance of glancing off bone

- Continue cutting after initial resistance

Durability and edge geometry work together to determine how effectively a blade performs in these situations.

Matching Blade Design to Your Setup

No blade design works in isolation. Arrow weight, bow energy, and shooting distance all influence how a blade performs.

Matching components properly:

- Maximizes penetration potential

- Preserves accuracy

- Improves confidence in real-world conditions

Testing and tuning help ensure that blade design complements the rest of the setup.

Conclusion

Blade design has a direct impact on penetration, durability, and effectiveness. Even small differences in angle, thickness, and profile can significantly alter performance. By understanding these factors, hunters can choose equipment that performs reliably under pressure. A well-designed blade supports ethical hunting by delivering clean, consistent results and minimizing the risk of equipment failure. Paying attention to blade design is about making informed choices that lead to better outcomes in the field.